Turnbuckle breaking loads are first determined by the thread diameter. This breaking load must be coordinated with the breaking load for the cable being used.

In other cases (forks for example), it is the shaft that defines the part strength, which must be coordinated with the strength of the cable being used.

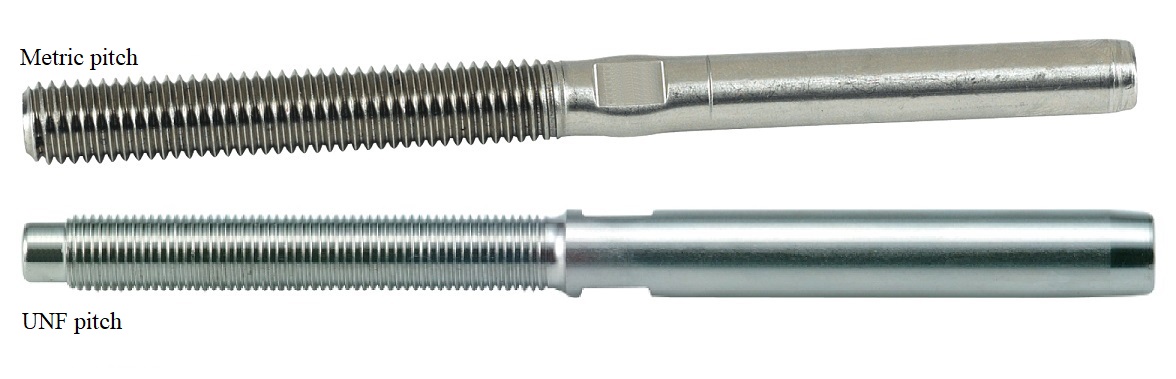

The metric (ISO) pitch is the most widely used thread in industry and construction (except of course in countries under the influence of hamburgers, ...). The widest choice of accessories is available for this ISO standard.

For the same diameter, the English "UNF" pitch provides better strength and more precise adjustment. That type of thread is traditionally used for sail boat rigging.

But the range and diversity of technical solutions is more limited.

To compare the aspects of the 2 types of thread (of identical diameter):

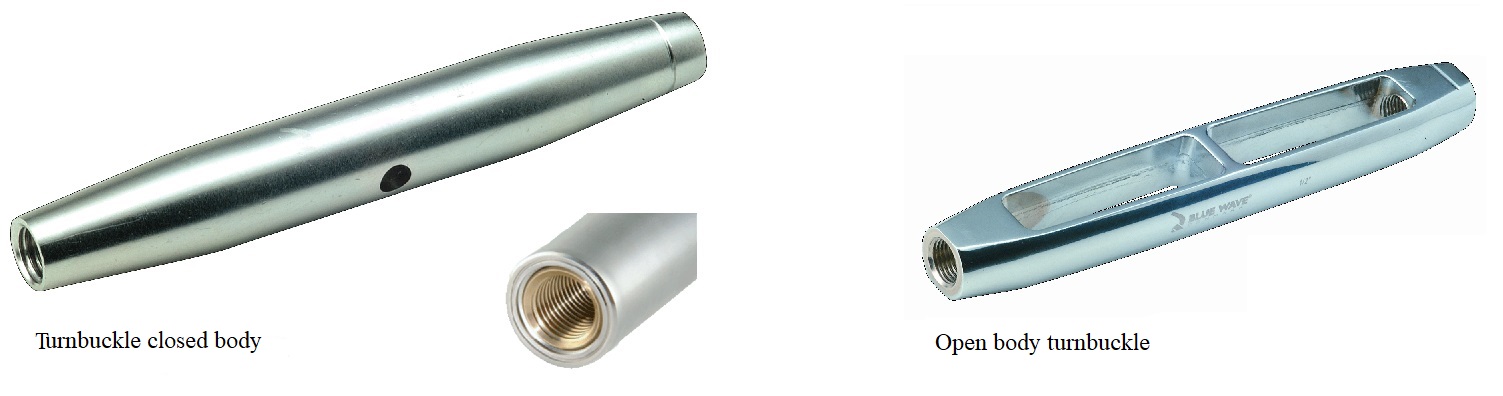

Stainless steel "closed body" turnbuckles* are the most common and cheapest models. Wide range of sizes from M5 to M60!

Simple and robust, it can have a defect in polluted environments: the closed body can trap dirt (dust, salts, etc.) that is difficult to clear away, and thus generate a seizure (jamming) risk over time.

To prevent risks of seizure under heavy loads, the stainless steel closed bodies are equipped with bronze bushings from M22 threads upwards.

It is always wise to apply a little special stainless steel grease during assembly, and then regularly (during the annual installation inspection).

Risk of seizure => generously grease the inside of the body.

Open chromium-plated bronze bodies are recommended for particularly difficult environments (salty or polluted air) and for heavy loads. The difference in hardness between stainless steel and bronze makes seizure almost impossible and allows for perfect thread cleaning.

All MARINE range turnbuckle bodies have a left threading identification mark. Which is a rare thing in the current market :)

Our wide range of turnbuckle accessories* makes it possible to replace damaged or lost parts,

but above all to compose a complete or partial turnbuckle adapted to your use.

INOX SYSTEM can study and produce specific models according to your specifications on request.

Our design office is at your service for the design / production of parts specific to your projects.

* Glossary:

Turnbuckle = tensioner